数控六面钻 KD-612G | 侧铣主轴可360°旋转,实现高定工艺加工

2024-02-22 来自: 兰州九力机电设备有限责任公司 浏览次数:186

数控六面钻 KD-612G | 侧铣主轴可360°旋转,实现高定工艺加工

HIGHLIGHTS

Spindle For Side Routering

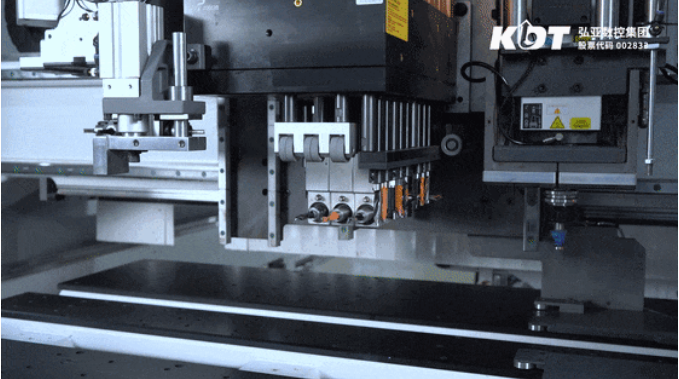

钻包左侧带C轴9kW侧铣主轴,可360度旋转,实现板件的四面铣型。

9kw spindle with C axis equiped on left side of the drill set, available for 360° turning to realize side routering.

上钻包增加钻杆数量,可实现三合一孔、台阶钻的加工。

Increase the quantity of horizantal drill shafts in upper drill set,available to make 3 in 1 drill and step drills.

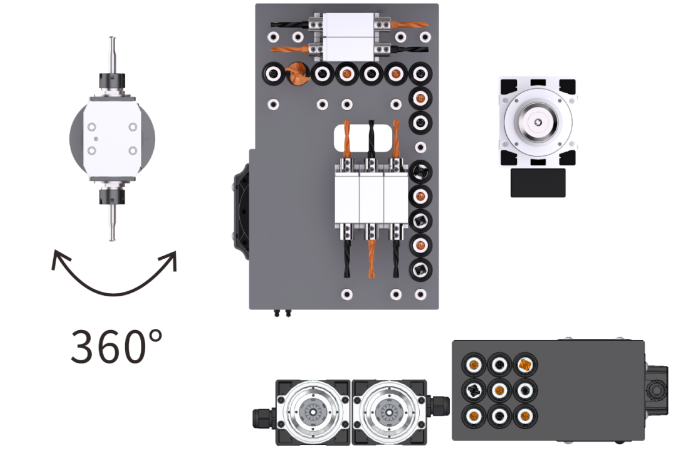

Layout of the Operation Unit

14V+10H上钻包,9V下钻包

Upper drill set:14V+10H,lower drill set:9V.

Dual Bottom Spindles

免频繁换刀,提高其效率。

Reduce the times in tools changing,thus to improve efficency.

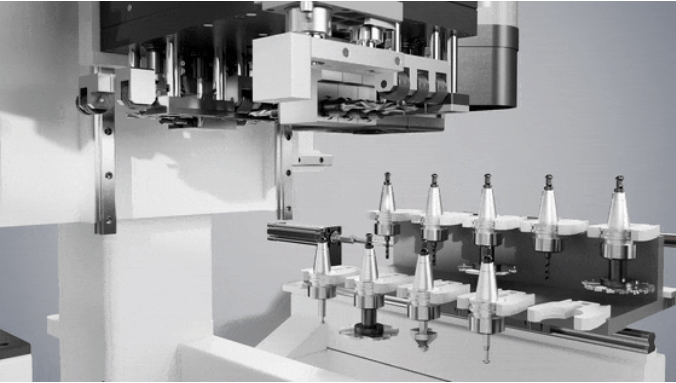

2-layers ATC With Total 10-fold

换刀速度快、自动对刀,满足多种隐形连接件复杂铣型、切边的工艺需求。

Quick tools change, auto tools pre-setter,satisfying demands in process various invisible fittings, routering and side cutting.

2-post ATC On Left Side

标配一字侧铣直角头,选配45°、十字或带锯片侧铣直角头。

Aggregate with 2-way outlets come as standard, options for 45° degree ,4-way oulets or side aggregate.

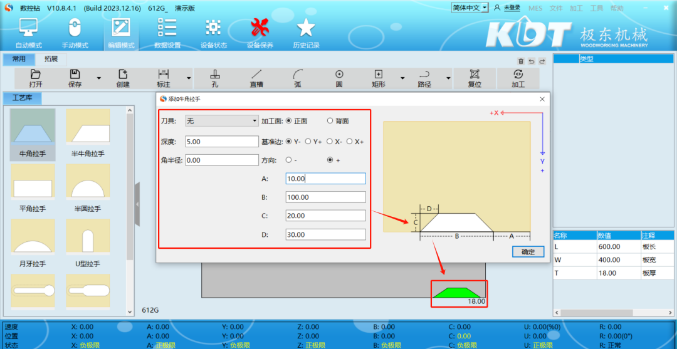

Upgraded Software

前瞻式打孔:通过智能AI蚁群算法,规划路径,钻杆实现提前输出,效率提升15%。

Proactive drilling: Plan the optimal path according to AI ant Algorithm, drill shaft pre-ejects out, increasing efficient work by 15% .

Diversified Process Libraries

灵活调用,简单编辑,程序自动生成加工路径。

Flexible calls for the required machining ,simple editing and automatic generation of machining path

CONFIGURATIONS

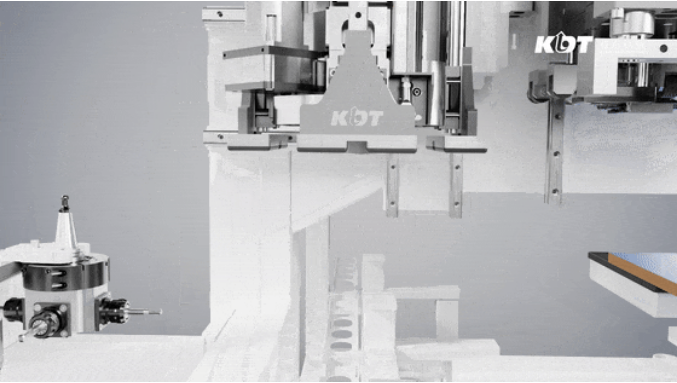

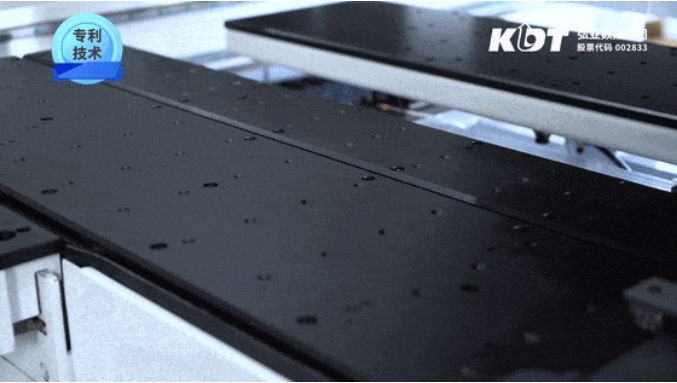

Air-floatation worktable

多段行程的双平移气浮台,避让更智能、支撑更合理。

Air-floatation worktable structured with multi-sectional travels intelligently prevents collision and leads to stronger support.

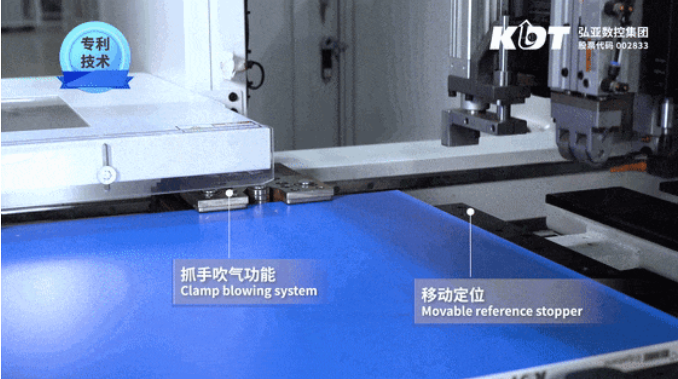

Clamp with auto-cleaning system

5.5米抓手导轨,抓手移动速度140m/min。

5500mm clamp stroke equipped, max.moving speed is up to140m/min.

有效吹净板面灰尘,贴合更充分抓取更牢固,钻孔更准。

Effectively blow off the dust,leading to a tight gripping and accurate drilling.

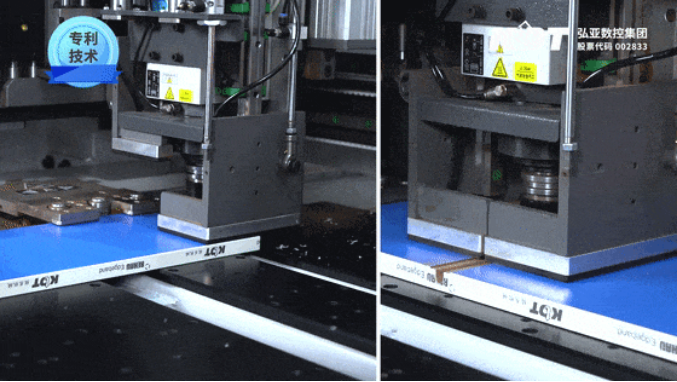

3 Bearing rods

小板定位准,换手不伤板。

Ensure accurate positions with small boards and no damage on workpiece edge in clamp changeover.

Pressure plate

压板覆盖面积广,加工振动小、精度高保护板材不被划伤。

Large pressure area, less vibration, high accuracy,and less risks on panel scratches.

DIVERSIFIED PROCESS LIBRARIES