产品介绍

斜边封边机可广泛应用于免拉手橱柜门、卫浴柜门、抽屉、办公台面等家具的封边,经过系列加工,实现高品质的斜面封边效果。

极东机械紧跟行业简约风流行趋势,

全新推出高品质斜边封边机,

为呈现斜边工艺倾力打造,

满足封边工艺个性化需求,

快随我一起解锁新产品亮点功能!

外观欣赏

Appearance Appreciation

适用范围

Application

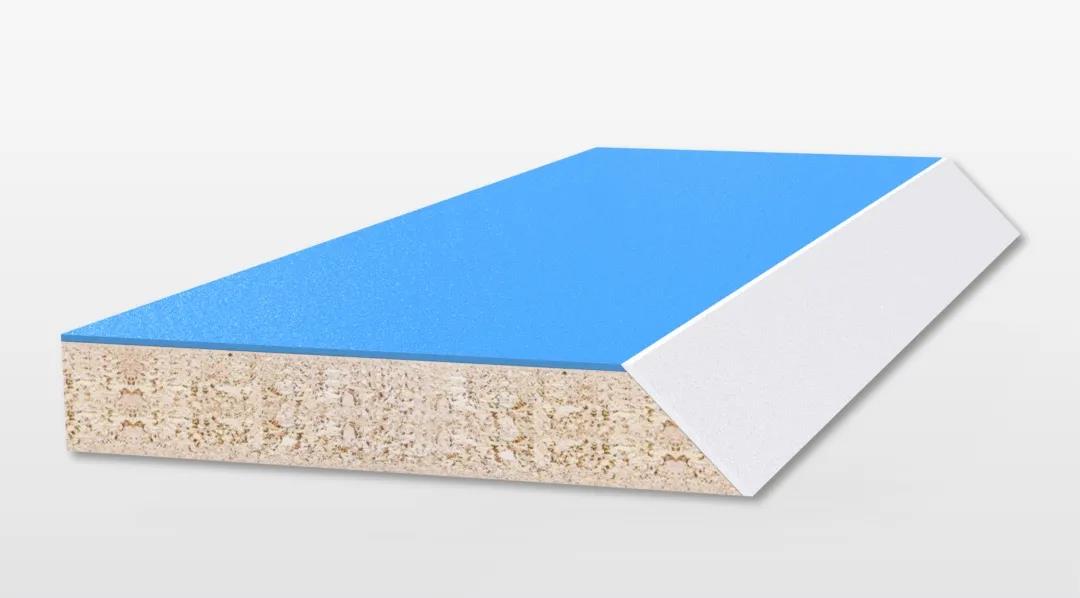

固定45°全斜边

Fixed 45° Bevel

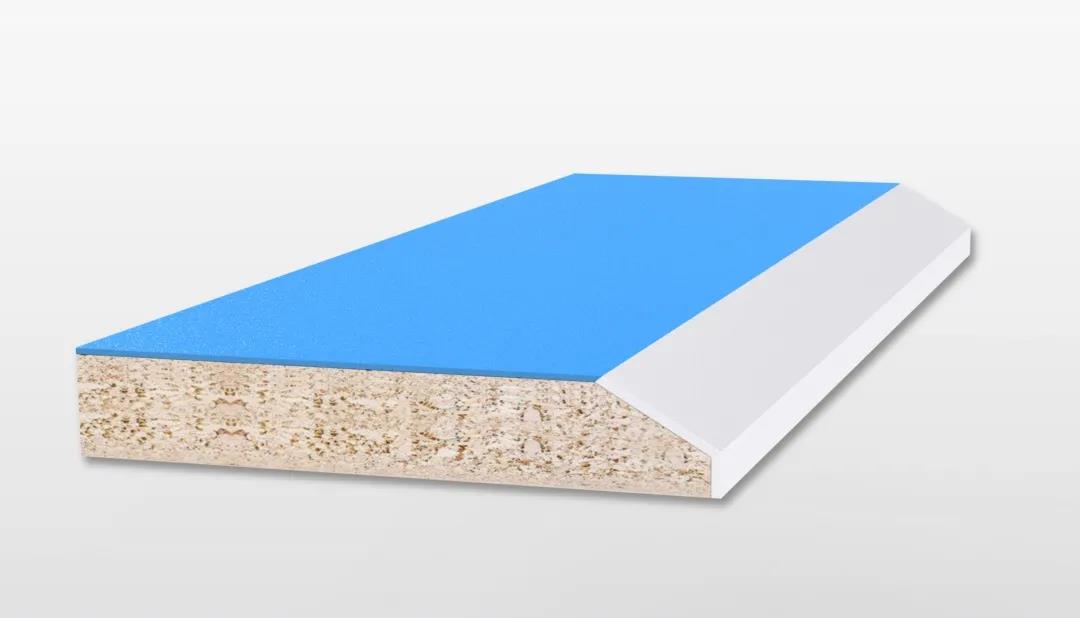

固定45°部分封边

Fixed 45° Chamfer

核心亮点·Highlights

预铣机构

Pre-milling Mechanism

高速锯切并粉碎切削板件边缘,

预先将板件斜直面铣平整,

使斜直面封边效果更出色。

High-speed cutting and crushing

panel edge, pre-mill panel

to be smooth bevel ,acquire

better bevel edge banding effect.

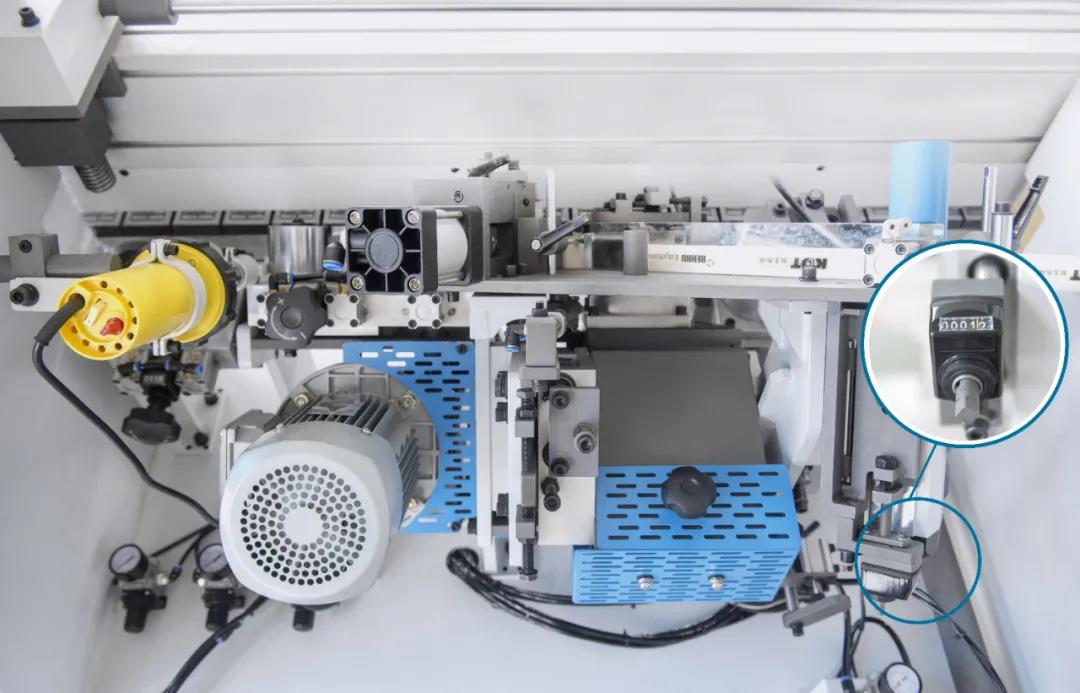

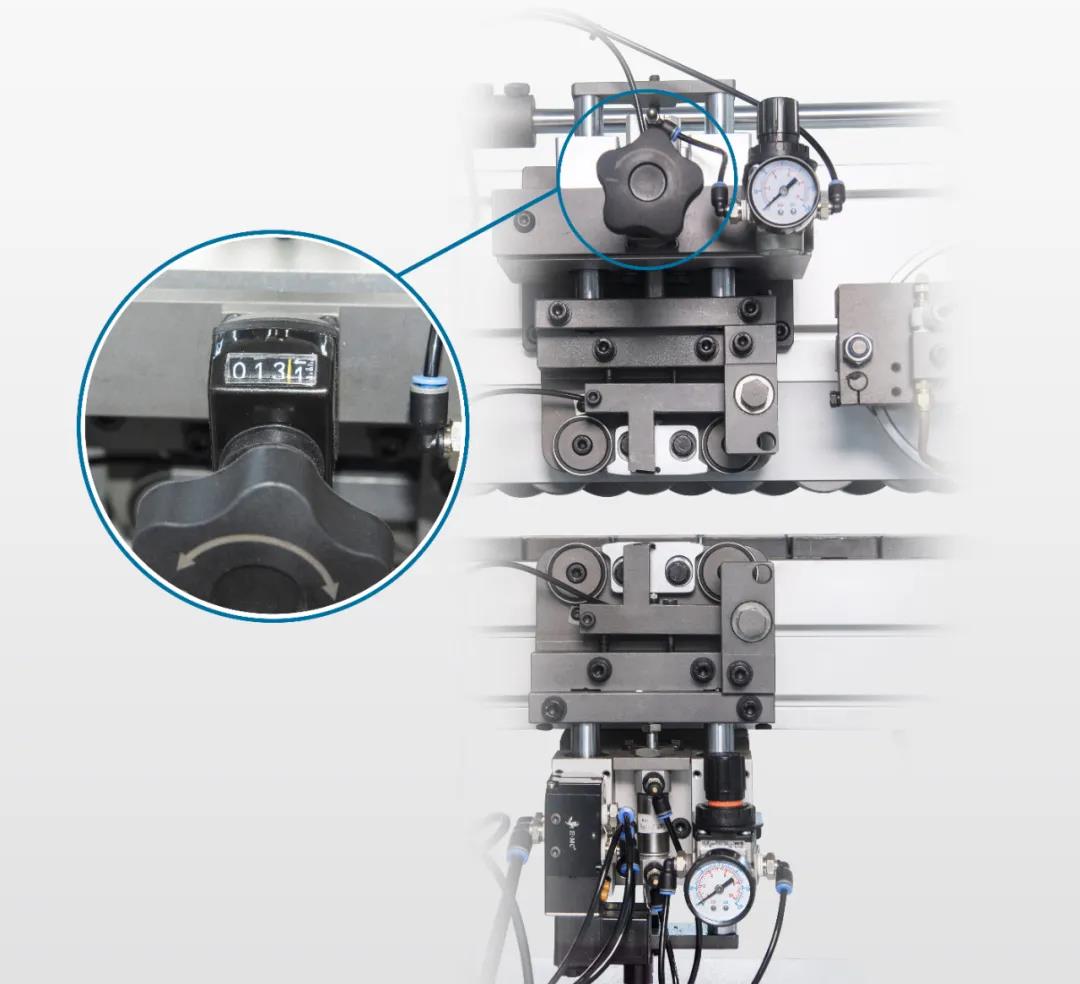

涂胶机构

Gluing Mechanism

斜直边均匀涂胶,

无缝粘合斜面封边,

配置计数器调节直观便捷。

Glue the bevel & vertical edge evenly,

seamless bevel edge banding ,

equipped with counter for convenient

and intuitive adjustment.

刮边机构

Scraping Mechanism

配备上下边刮刀,

使斜边封边上下边缘弧度更加圆润美观。

Equipped with top and bottom

scraping to make panel edge

smoother and better-looking.

平刮边机构

Flat scraping Mechanism

配置计数器直观调节上平刮边,

去除残留胶水,使封边更加清洁美观。

Equipped with counter for visual

adjustment of top flat scraping,

remove extra glue to make surface cleaner.

变频控制机构

Controlled by Converter

整机高速电机采用变频控制,

运行稳定节能。

The high-speed motor of the

whole machine is control by inverter,

which is stable and power saving for customer.

重要配置·Other Features

齐头机构

End-cutting Mechanism

将工件首尾封边带切断,

控制带前带后用量,保证切断面平整光滑。

Cut the edge at front

and back side of workpiece,

reduce edge waste at front&back

side of workpiece also ensure

smooth cutting surface.

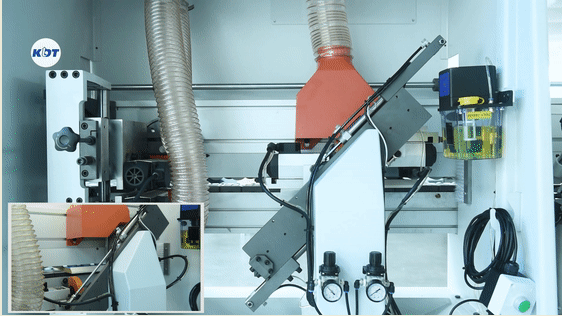

粗修、精修机构

Rough Trimming

修去加工板材封边条上下多余的封边材料,

保证修边的板材上下部分的平整光滑。

Used to trim off the excess

edge tape at topand bottom,

assuriang a flat and smooth surface.

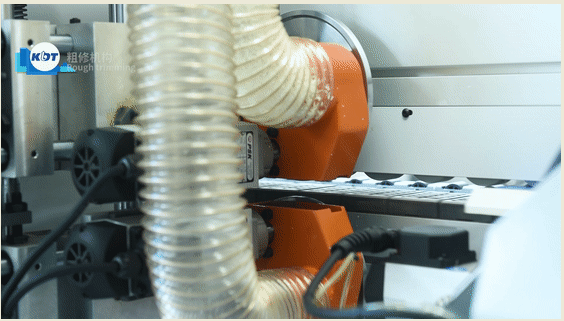

固定式抛光机构

Fixed Buffing Mechanism

消除多余胶痕,使封边带表面更加光滑。

Remove extra glue to make

the edge banding surface smoother.

压梁自动定位系统

Pressure Beam Positioning System

可快速切换加工不同厚度的板件,

减少调机时间,提高其效率。

Pressure beam can be switched quickly

according to boards of different thickness

and processed to reduce machine

adjustment time, which improves efficiency.

技术参数·Parameters